DC motor position control using PID

In this video I show you a very basic example of PID-controlled DC motor positioning. The core of the PID-based position control is to have an encoder which provides a feedback for the PID code which can determine the control signal for the motor. For example, the user has to define a target position (setpoint) in terms of encoder pulses which is passed to the PID code which in exchange generates a control signal that we can use to drive the motor. The PID (Proportional-Integral-Derivative) controller has three parameters (P, I and D) that we need to tune so the system will give an appropriate response for a given set point.

This is a very basic video on PID and the code and the implementation is probably not the best practice, but it is enough to get started and learn the rest by experimenting and studying other people’s articles, videos…etc.

Schematics

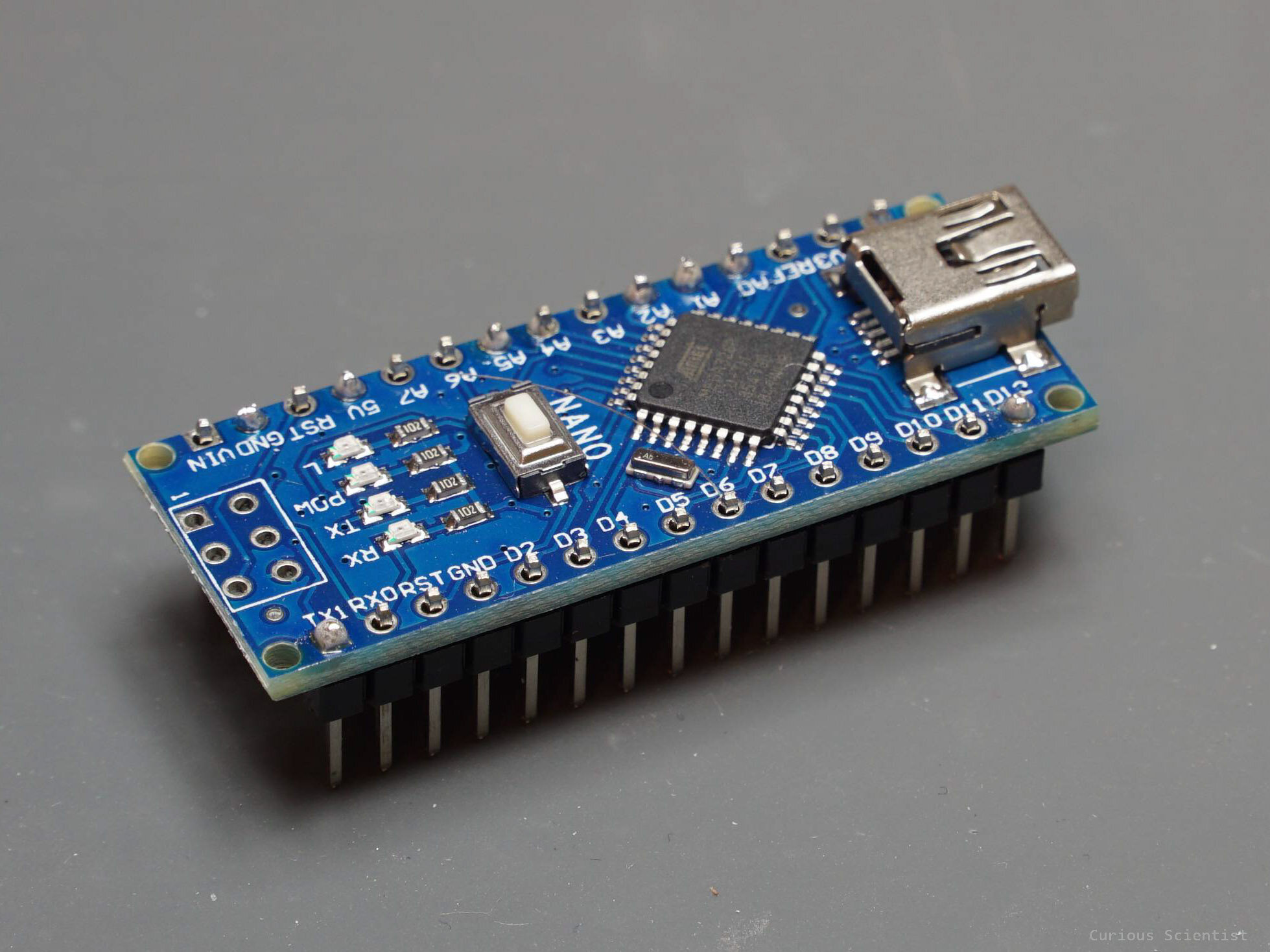

The core of the circuit is an Arduino Nano. I use 3.3 V for all the logical voltages (orange wires). The connections are also indicated in a text form.

Arduino source code

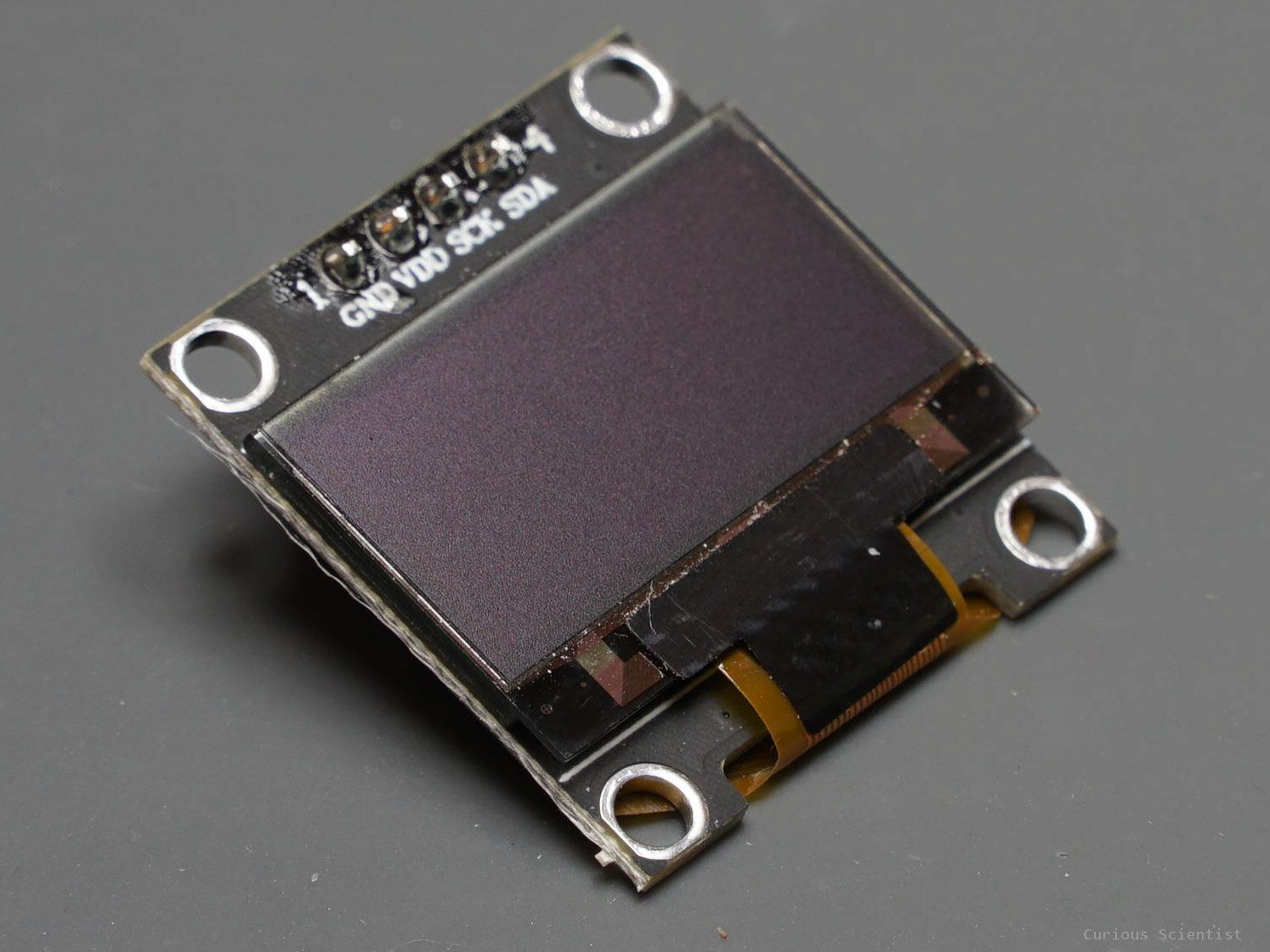

#include <Wire.h> //This is for i2C #include <SSD1306Ascii.h> //i2C OLED #include <SSD1306AsciiWire.h> //i2C OLED #define I2C_ADDRESS 0x3C #define RST_PIN -1 SSD1306AsciiWire oled; float OLEDTimer = 0; //Timer for the display refresh interval //I2C pins: //STM32F103C8T6: SDA: PB7 SCL: PB6 //Arduino: SDA: A4 SCL: A5 //--------------------------------------------------------------------------- //Input and output pins //Motor encoder const int encoderPin1 = 3; //this pin is also the interrupt pin! const int encoderPin2 = 4; //this pin is a normal pin, read upon the interrupt int encoderPin2Value = 0; //value of the encoder pin (0 or 1), this pin is read inside the interrupt - used for direction determination //---------------------------------- //PWM motor driver const int PWMPin = 11; //this is an analog pin (with the tilde (~) symbol), this pin can also do higher frequency + independent from millis()'s timer int PWMValue = 0; //0-255 PWM value for speed, external PWM boards can go higher (e.g. PCA9685: 12-bit => 0-4095) const int directionPin1 = 10; //digital pin, output, sets the direction const int directionPin2 = 9; //digital pin, output, sets the direction const int standByPin = 6; //STDBY pin, must be active high. Stops the H-bridge. int motorDirection = 0; //direction value 0: CCW, 1: CW. - Stored value //---------------------------------- //Rotary encoder const int RotaryCLK = 2; //CLK pin on the rotary encoder, interrupt pin! const int RotaryDT = 7; //DT pin on the rotary encoder, read inside the interrupt const int RotarySW = 8; //SW pin on the rotary encoder (Button function) int RotaryButtonValue = 0; //0 or 1 (pressed or not) float RotaryTime; //timer for debouncing volatile int rotaryValue = 0; //value manipulated by the encoder int previousRotaryValue = -1; //a variable which stores the previous value - easy to follow changes //---------------------- //Target values - Also called as setpoint! float targetPosition = 0; //the PID will try to reach this value //----------------------- //Measured values volatile float motorPosition = 0; //position based on the encoder float previousMotorPosition = -1; //helps to keep track of changes (useful for the display update) //----------------------------------- //----------------------------------- //PID parameters - tuned by the user float proportional = 1.35; //k_p = 0.5 float integral = 0.00005; //k_i = 3 float derivative = 0.01; //k_d = 1 float controlSignal = 0; //u - Also called as process variable (PV) //----------------------------------- //----------------------------------- //PID-related float previousTime = 0; //for calculating delta t float previousError = 0; //for calculating the derivative (edot) float errorIntegral = 0; //integral error float currentTime = 0; //time in the moment of calculation float deltaTime = 0; //time difference float errorValue = 0; //error float edot = 0; //derivative (de/dt) //Statuses of the DT and CLK pins on the encoder int CLKNow; int CLKPrevious; int DTNow; int DTPrevious; void setup() { Serial.begin(115200); Wire.begin(); //start i2C Wire.setClock(800000L); //faster clock //Motor encoder-related pinMode(encoderPin1, INPUT); //A pinMode(encoderPin2, INPUT); //B attachInterrupt(digitalPinToInterrupt(encoderPin1), checkEncoder, RISING); pinMode(standByPin, OUTPUT); // //Definition of the pins, remember where you need pinMode(RotaryCLK, INPUT_PULLUP); //CLK pinMode(RotaryDT, INPUT_PULLUP); //DT pinMode(RotarySW, INPUT_PULLUP); //SW attachInterrupt(digitalPinToInterrupt(RotaryCLK), RotaryEncoder, CHANGE); //Store states CLKPrevious = digitalRead(RotaryCLK); DTPrevious = digitalRead(RotaryDT); //------------------------------------------------------------------------------ //OLED part #if RST_PIN >= 0 oled.begin(&Adafruit128x32, I2C_ADDRESS, RST_PIN); #else // RST_PIN >= 0 oled.begin(&Adafruit128x32, I2C_ADDRESS); #endif // RST_PIN >= 0 oled.setFont(Adafruit5x7); oled.clear(); //clear display oled.set2X(); // oled.println(" PID "); //print some welcome message oled.println("Controller"); oled.set1X(); delay(1000); OLEDTimer = millis(); //start the timer oled.clear(); displayPermanentItems(); refreshDisplay(); } void loop() { calculatePID(); driveMotor(); //printValues(); CheckRotaryButton(); refreshDisplay(); } void checkEncoder() { //We need to read the other pin of the encoder which will be either 1 or 0 depending on the direction encoderPin2Value = digitalRead(encoderPin2); if (encoderPin2Value == 1) //CW direction { motorPosition++; } else //else, it is zero... -> CCW direction { motorPosition--; } } void driveMotor() { //Determine speed and direction based on the value of the control signal //direction if (controlSignal < 0) //negative value: CCW { motorDirection = -1; } else if (controlSignal > 0) //positive: CW { motorDirection = 1; } else //0: STOP - this might be a bad practice when you overshoot the setpoint { motorDirection = 0; } //--------------------------------------------------------------------------- //Speed PWMValue = (int)fabs(controlSignal); //PWM values cannot be negative and have to be integers if (PWMValue > 255) //fabs() = floating point absolute value { PWMValue = 255; //capping the PWM signal - 8 bit } if (PWMValue < 30 && errorValue != 0) { PWMValue = 30; } //A little explanation for the "bottom capping": //Under a certain PWM value, there won't be enough current flowing through the coils of the motor //Therefore, despite the fact that the PWM value is set to the "correct" value, the motor will not move //The above value is an empirical value, it depends on the motors perhaps, but 30 seems to work well in my case //we set the direction - this is a user-defined value, adjusted for TB6612FNG driver if (motorDirection == -1) //-1 == CCW { digitalWrite(directionPin1, LOW); digitalWrite(directionPin2, HIGH); } else if (motorDirection == 1) // == 1, CW { digitalWrite(directionPin1, HIGH); digitalWrite(directionPin2, LOW); } else // == 0, stop/break { digitalWrite(directionPin1, LOW); digitalWrite(directionPin2, LOW); digitalWrite(standByPin, LOW); PWMValue = 0; //In this block we also shut down the motor and set the PWM to zero } //---------------------------------------------------- //Then we set the motor speed analogWrite(PWMPin, PWMValue); //Optional printing on the terminal to check what's up /* Serial.print(errorValue); Serial.print(" "); Serial.print(PWMValue); Serial.print(" "); Serial.print(targetPosition); Serial.print(" "); Serial.print(motorPosition); Serial.println(); */ } void calculatePID() { //Determining the elapsed time currentTime = micros(); //current time deltaTime = (currentTime - previousTime) / 1000000.0; //time difference in seconds previousTime = currentTime; //save the current time for the next iteration to get the time difference //--- errorValue = motorPosition - targetPosition; //Current position - target position (or setpoint) edot = (errorValue - previousError) / deltaTime; //edot = de/dt - derivative term errorIntegral = errorIntegral + (errorValue * deltaTime); //integral term - Newton-Leibniz, notice, this is a running sum! controlSignal = (proportional * errorValue) + (derivative * edot) + (integral * errorIntegral); //final sum, proportional term also calculated here previousError = errorValue; //save the error for the next iteration to get the difference (for edot) } void printValues() { //Serial.print("Position: "); Serial.println(motorPosition); } void displayPermanentItems() { //print the permanent items on the display oled.setCursor(0, 0); //(x [pixels], y[lines]) oled.print("Target"); oled.setCursor(0, 2); oled.print("Position"); } void refreshDisplay() { if (millis() - OLEDTimer > 100) //check if we will update at every 100 ms { if (previousRotaryValue != rotaryValue) { oled.setCursor(0, 1); oled.print(" "); oled.setCursor(0, 1); oled.print(rotaryValue); //print the target value set by the rotary encoder previousRotaryValue = rotaryValue; OLEDTimer = millis(); //reset timer } if (motorPosition != previousMotorPosition) { oled.setCursor(0, 3); oled.print(" "); oled.setCursor(0, 3); oled.print(motorPosition, 0); //print the new absolute position previousMotorPosition = motorPosition; OLEDTimer = millis(); //reset timer } } else { //skip } } void RotaryEncoder() { CLKNow = digitalRead(RotaryCLK); //Read the state of the CLK pin // If last and current state of CLK are different, then a pulse occurred if (CLKNow != CLKPrevious && CLKNow == 1) { if (digitalRead(RotaryDT) != CLKNow) //the increment/decrement can depend on the actual polarity of CLK and DT { rotaryValue = rotaryValue - 515 ; //1 } else { rotaryValue = rotaryValue + 515 ; //1 } } CLKPrevious = CLKNow; // Store last CLK state } void CheckRotaryButton() { RotaryButtonValue = digitalRead(RotarySW); //read the button state if (RotaryButtonValue == 0) //0 and 1 can differ based on the wiring { if (millis() - RotaryTime > 1000) { targetPosition = rotaryValue; //pass the setpoint (target value) to the corresponding variable digitalWrite(standByPin, HIGH); //enable motor driver RotaryTime = millis(); //save time } } }

Parts I used in this project

By clicking the pictures, you will be redirected to my affiliate links. If you purchase the products using these links, you support my work!

More parts can be found under the Tools section of my website!