Making my own reflow hot plate from scratch - Part 1 - Prototype

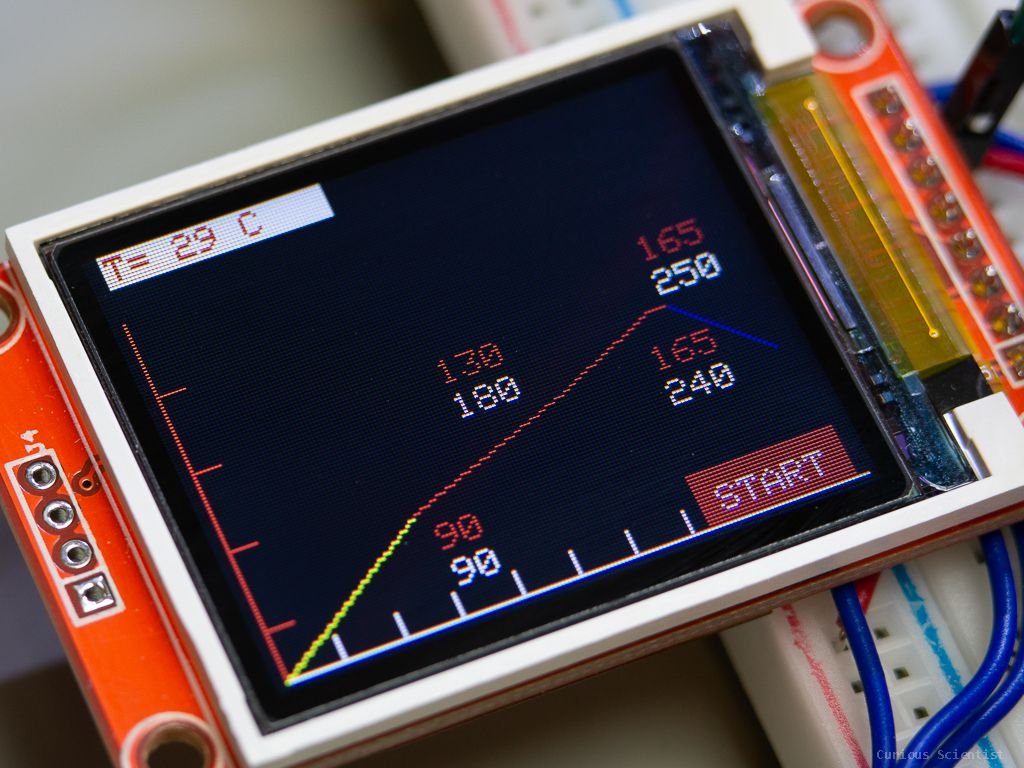

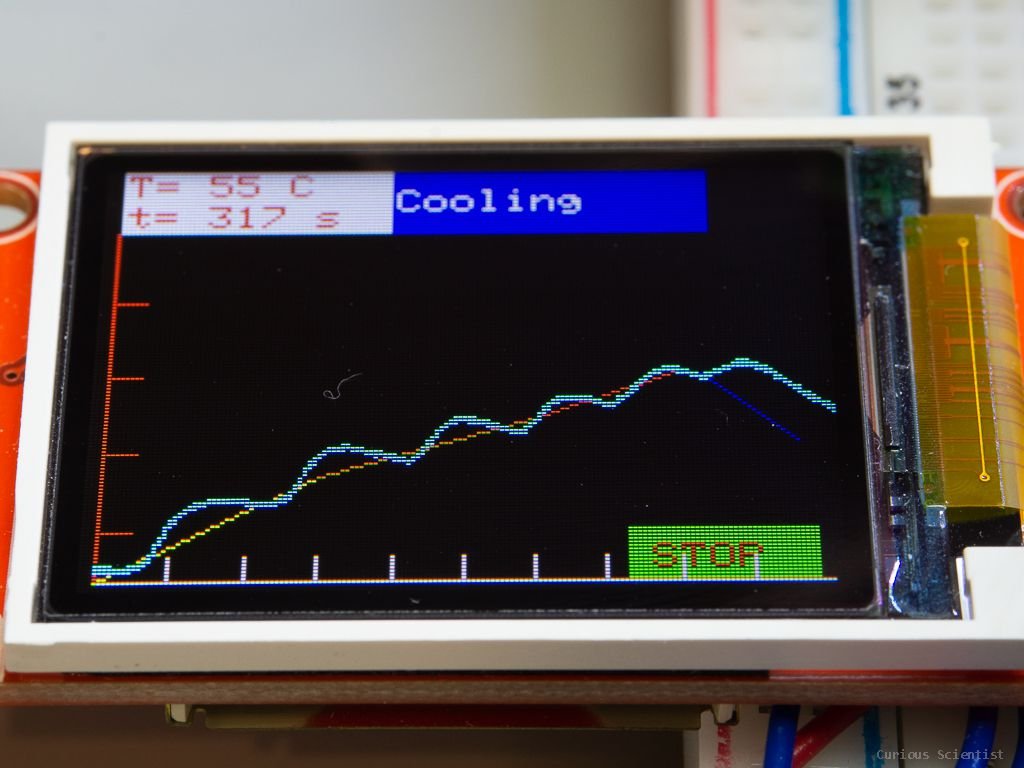

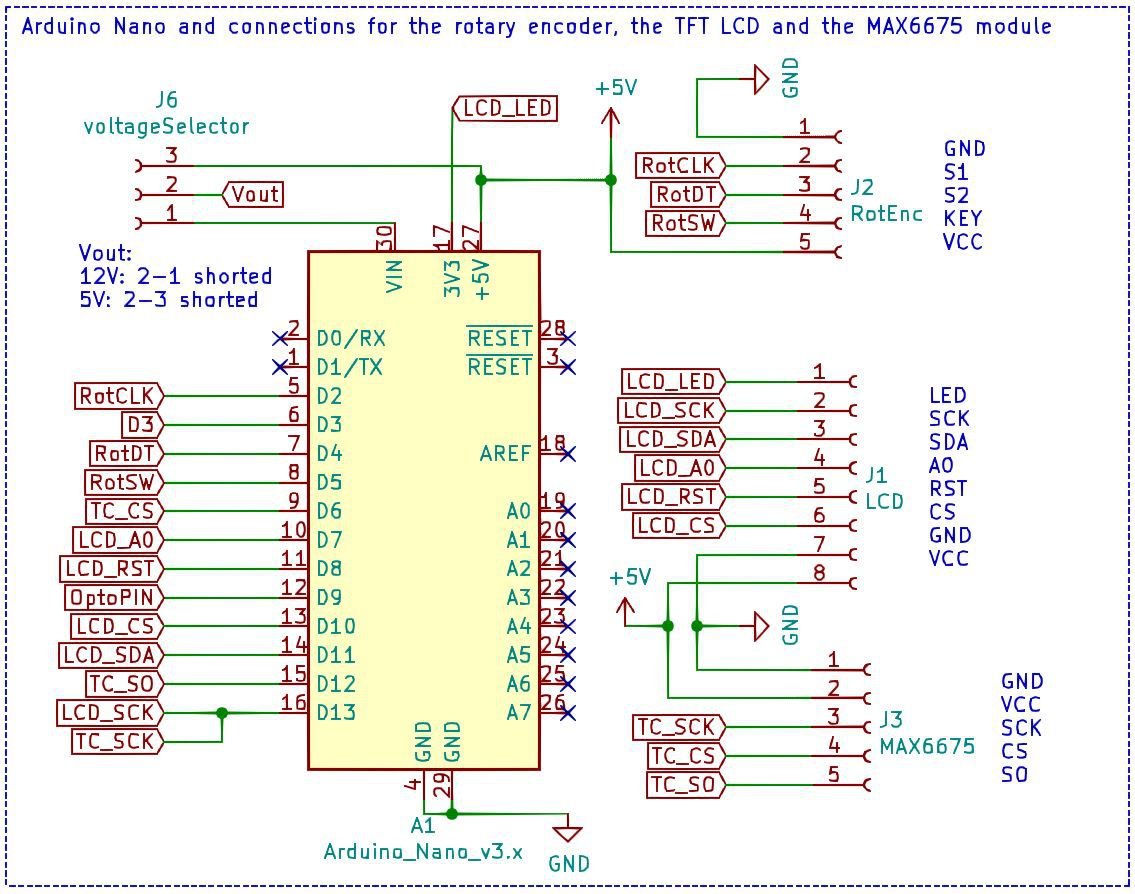

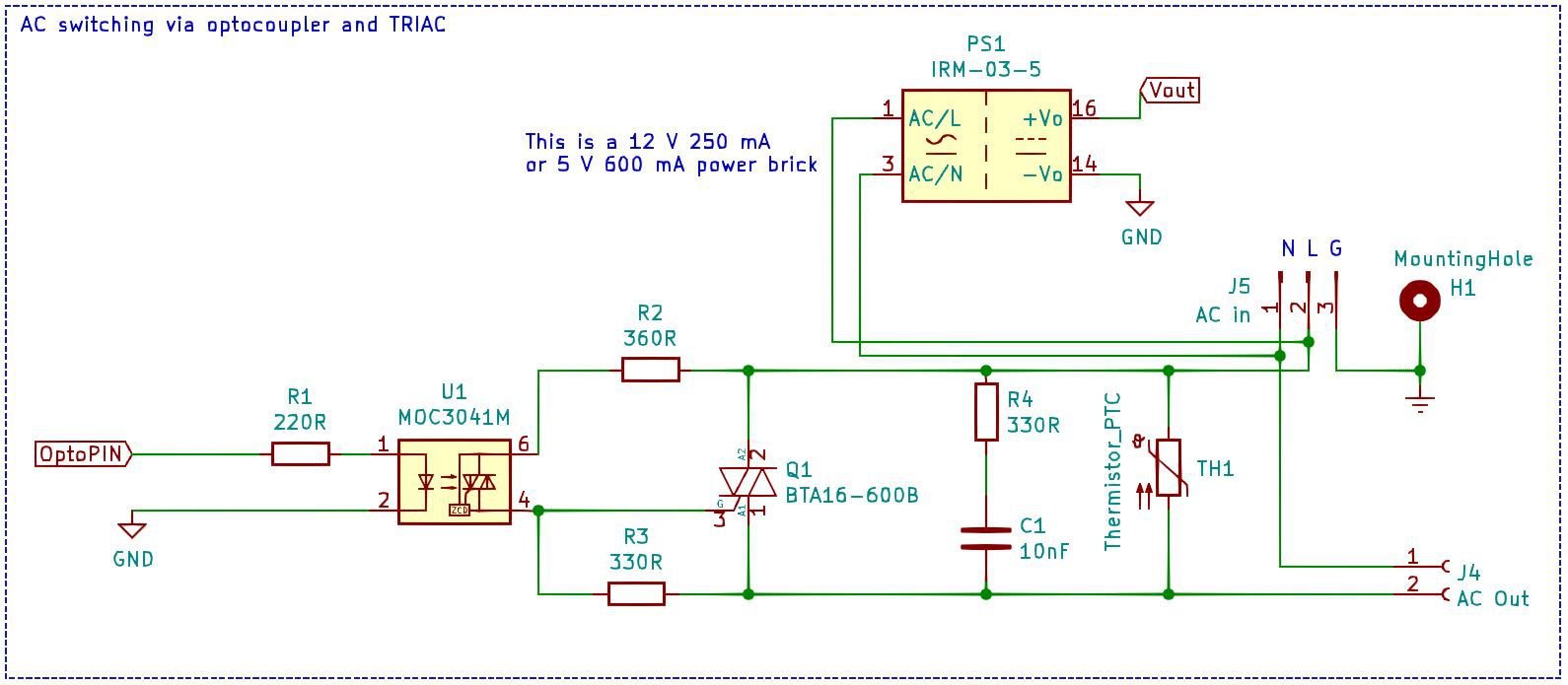

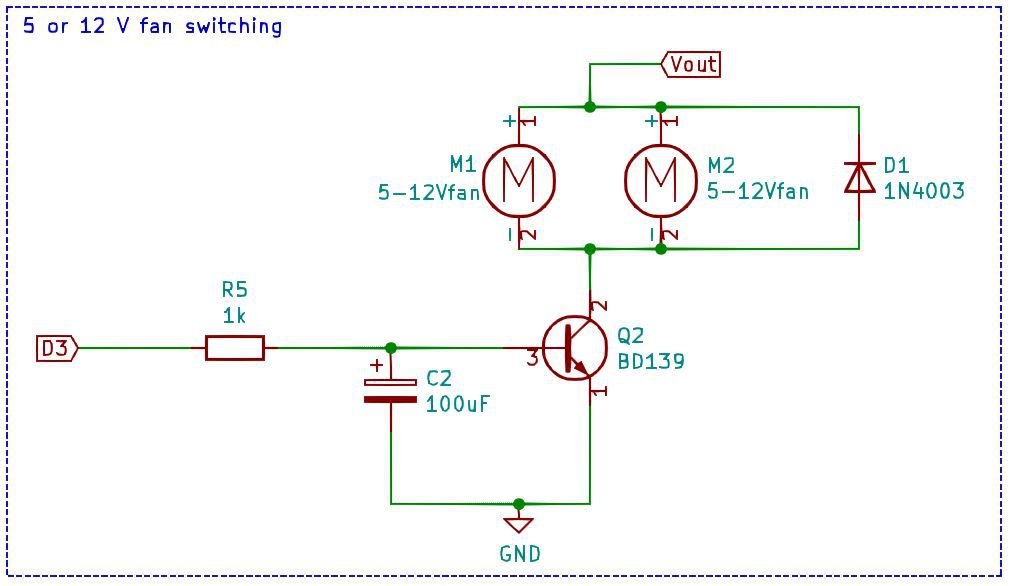

This is the first video of another video series on a project that I am working on. The subject this time is a fully customized reflow hot plate from scratch. I put together a relatively system using a few components as a first iteration. The system consists of an Arduino Nano as the main microcontroller, a MAX6675 K-type thermocouple module for measuring the temperature of the hot plate, a TRIAC switch circuit to switch the heating plate on and off and a 1.8” 128x160 TFT LCD to visualize everything. The controlling of the heating plate is very simple: I created a formula that based on the user-created reflow curve determines the temperature at a given moment and the code checks if we are above or below this temperature. The heater is turned on if we are below the target (or setpoint), and it turns off if we are above it. This is a very simple ON/OFF switching that has its drawbacks and advantages, but I can accept its drawbacks for the first iteration of this circuit.

Regarding the user interface, I went above and beyond and I tried to create a very flexible way of entering any kind of custom reflow curve. I also made it possible that during heating, a real-time time vs. temperature curve is being plotted over the user-defined reflow curve as well as information such as the target temperature, elapsed time, actual program…etc. is also shown.

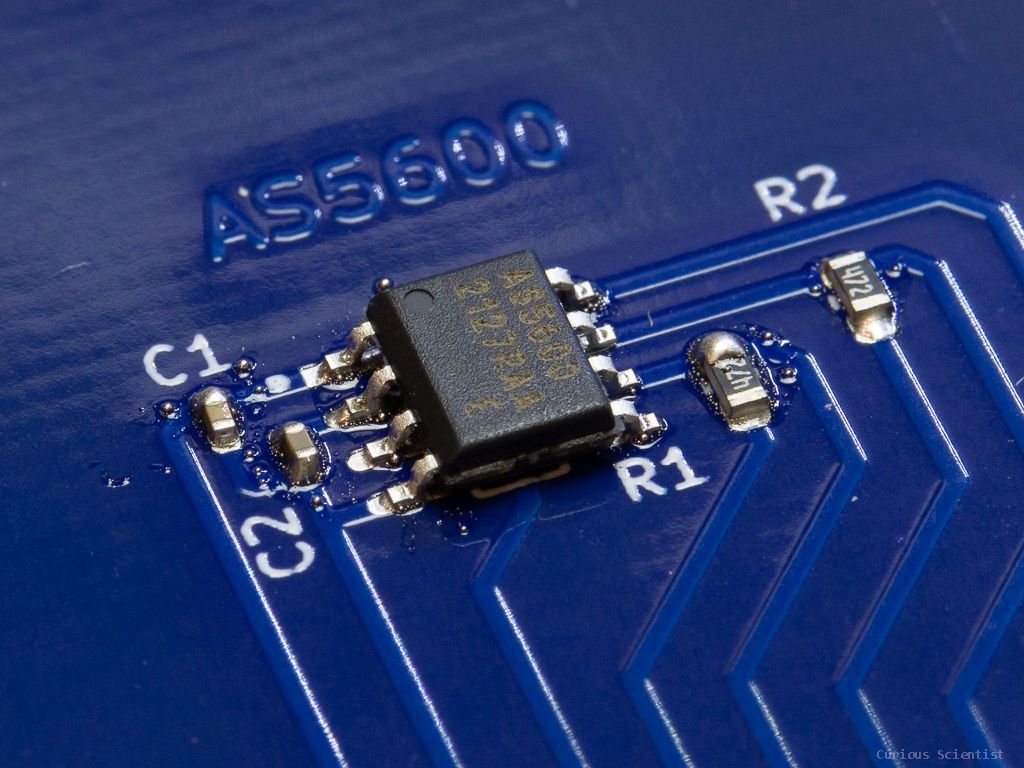

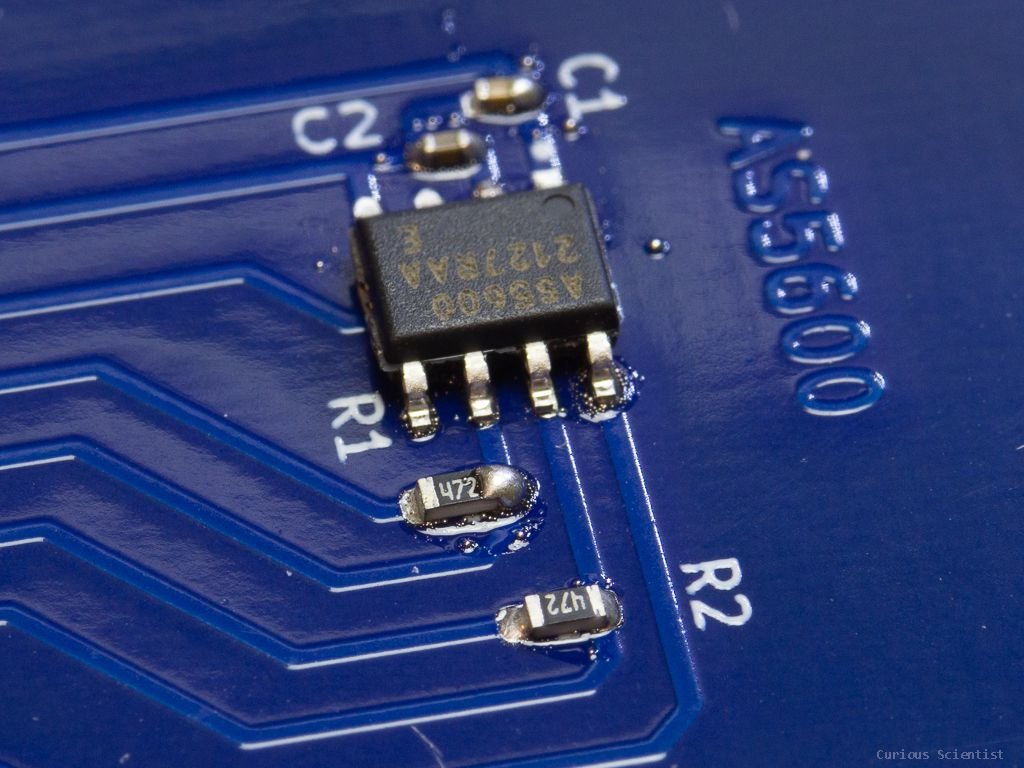

Schematics and some photos

You can buy the relevant parts using the following affiliate links:

Join my YouTube membership!