2500 W Induction melting system

This project has a funny background story. I worked a lot with induction melting in the past (alloy development) and in fact I still work with it during my daily job. But of course this 2.5 kW equipment cannot be compared to the 15 kW unit that I use at work. Nevertheless, I faced some obstacles that I could not solve at my workplace and due to the strict (but fair) safety regulations I am not allowed to hack the induction melting equipment. So, out of frustration I started to build my own miniaturized melting equipment that I will use as a proof of concept to show that my idea should/would work.

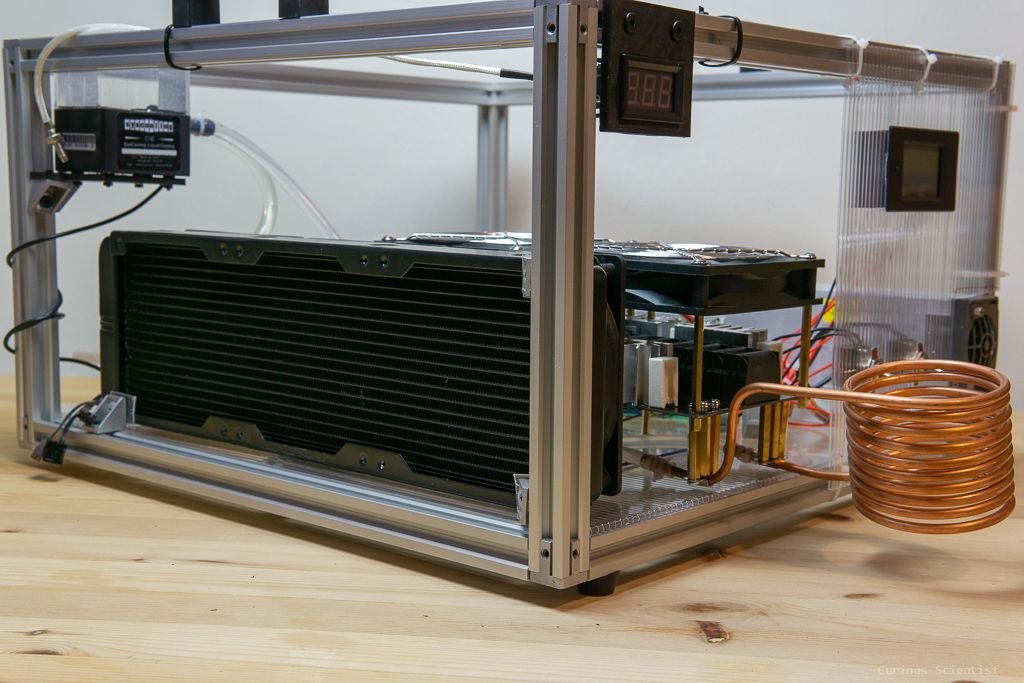

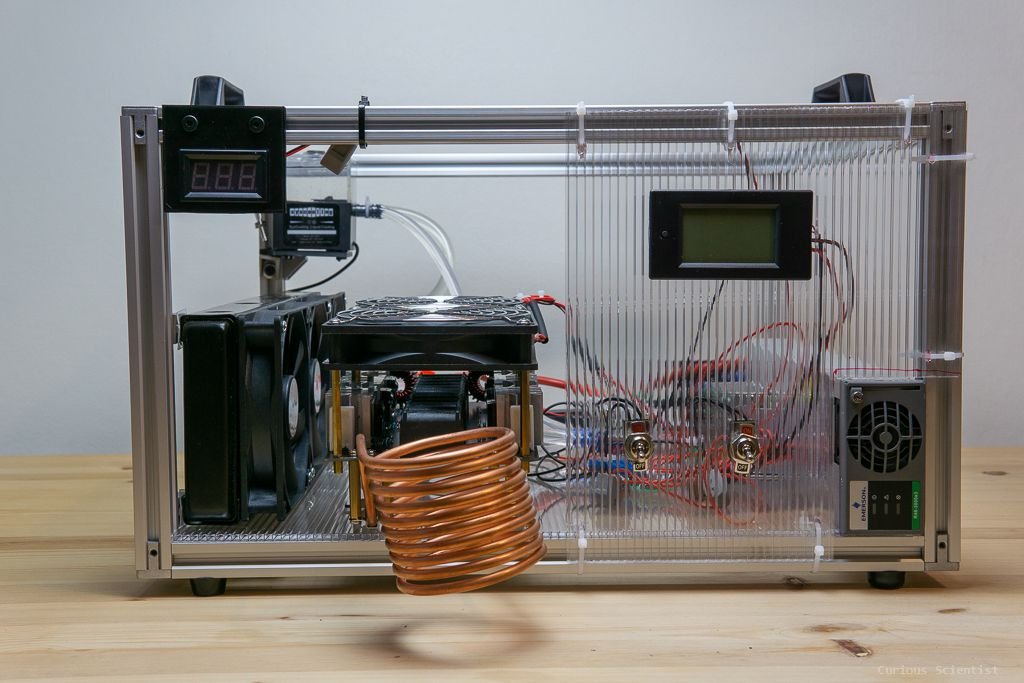

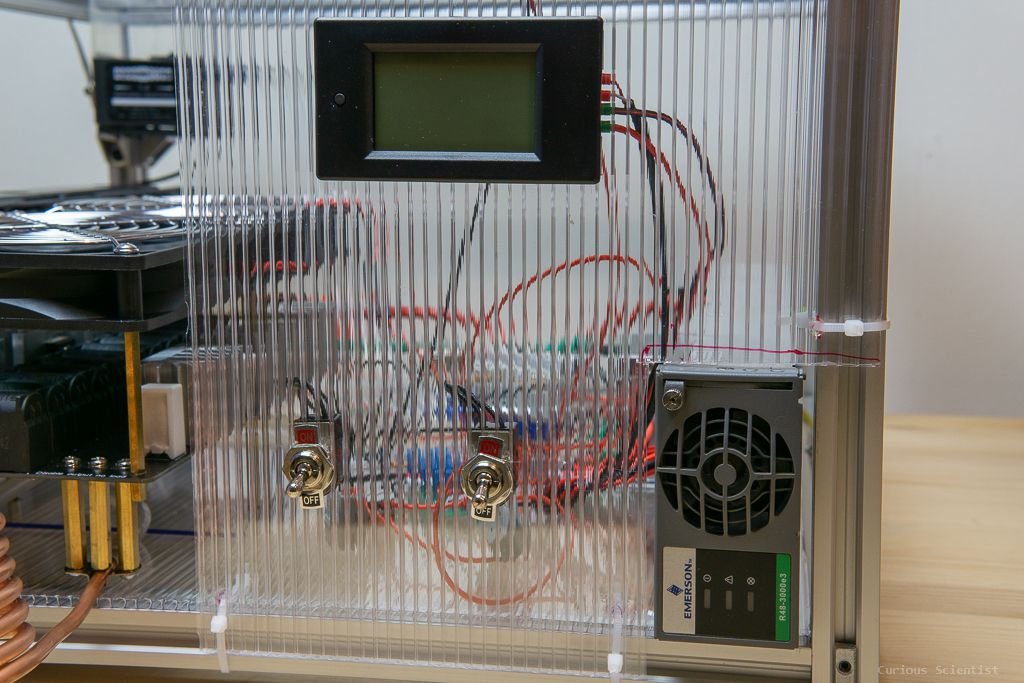

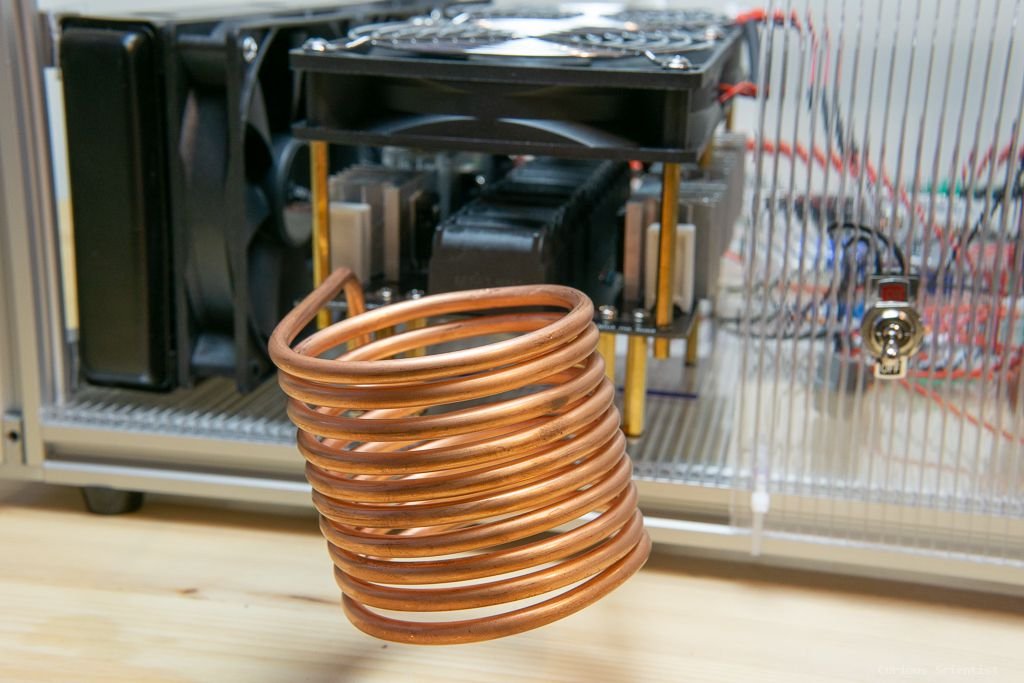

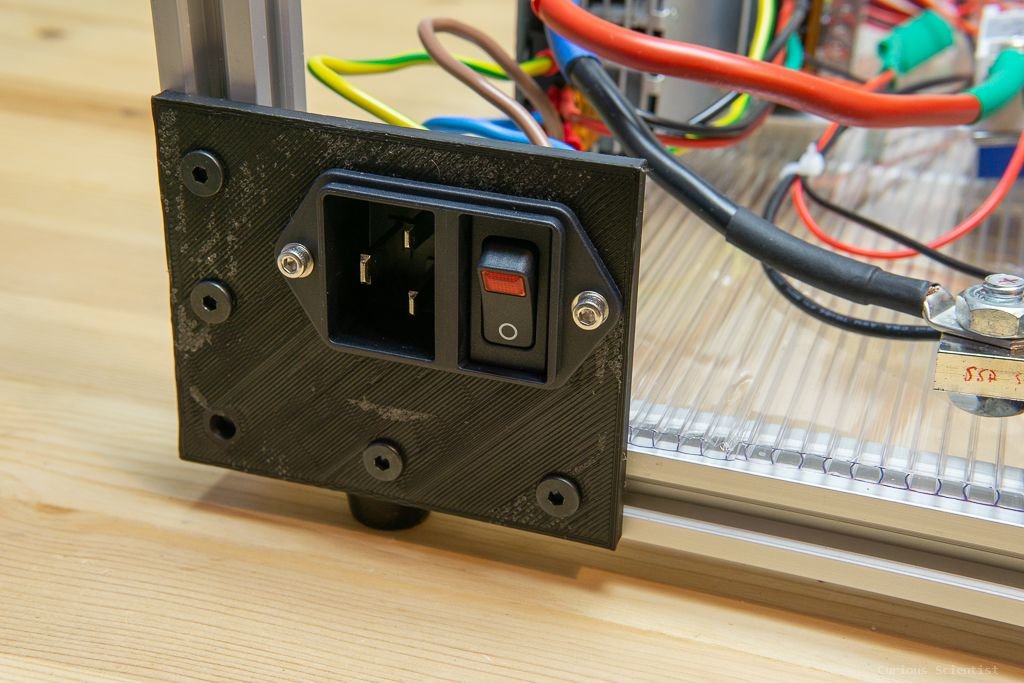

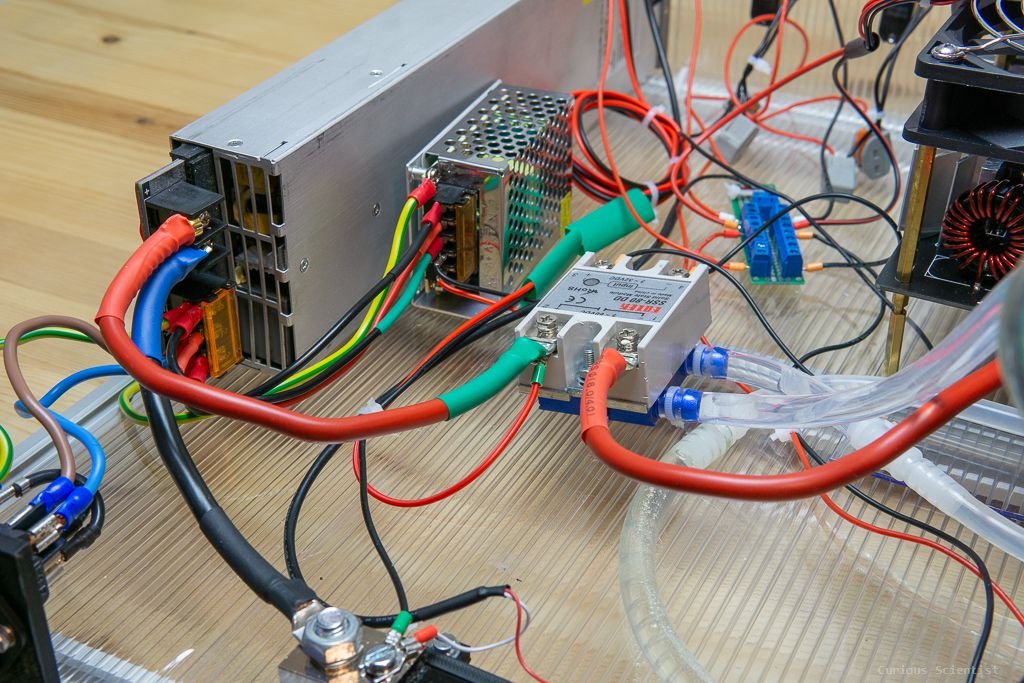

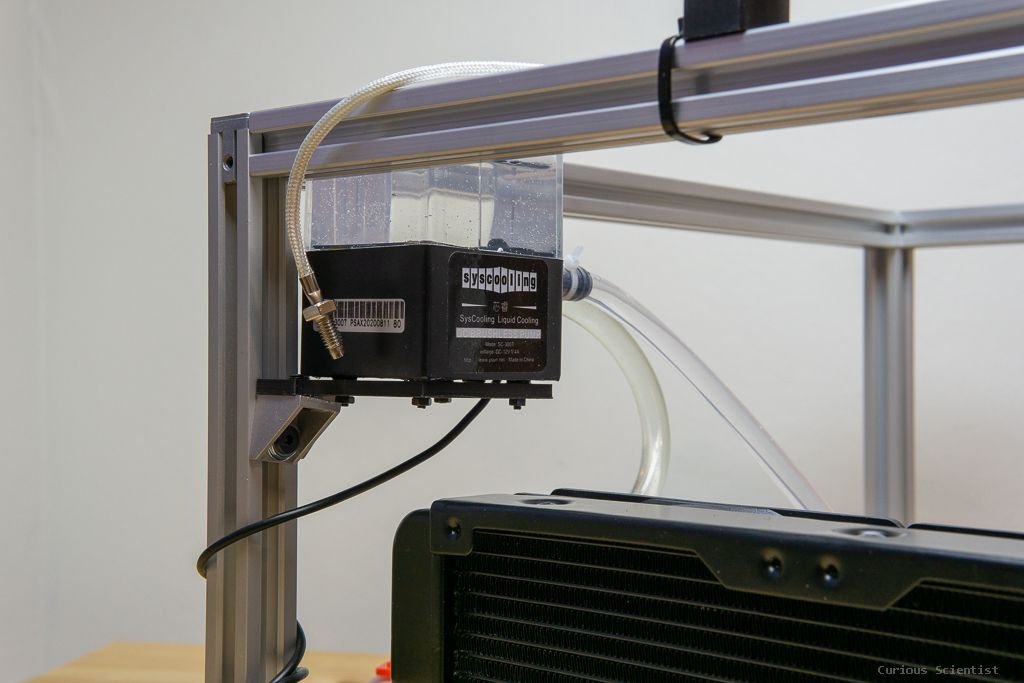

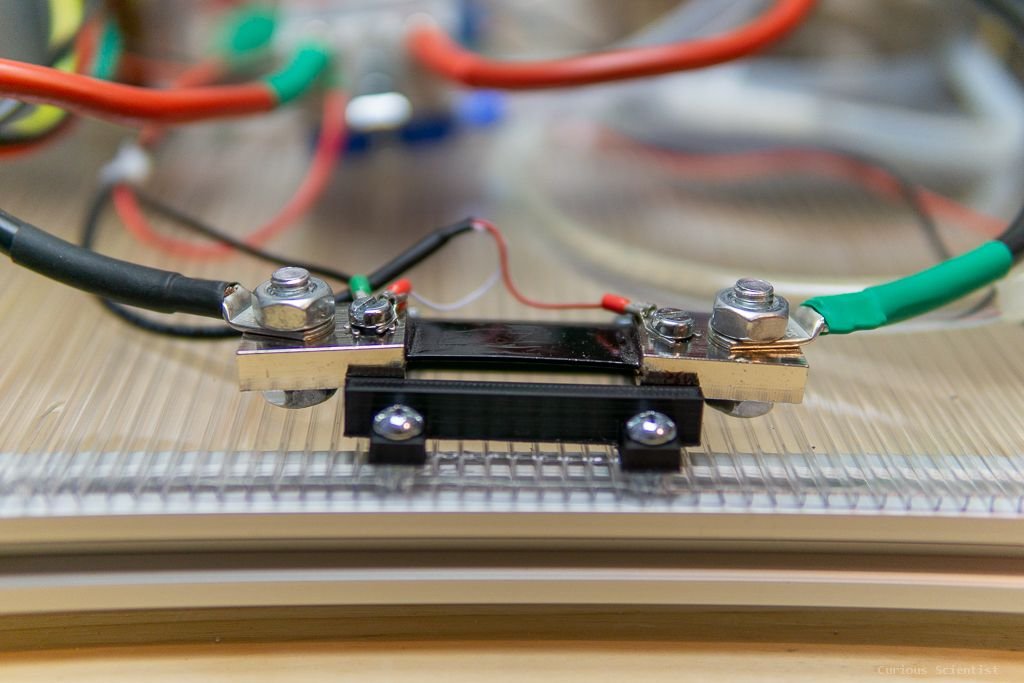

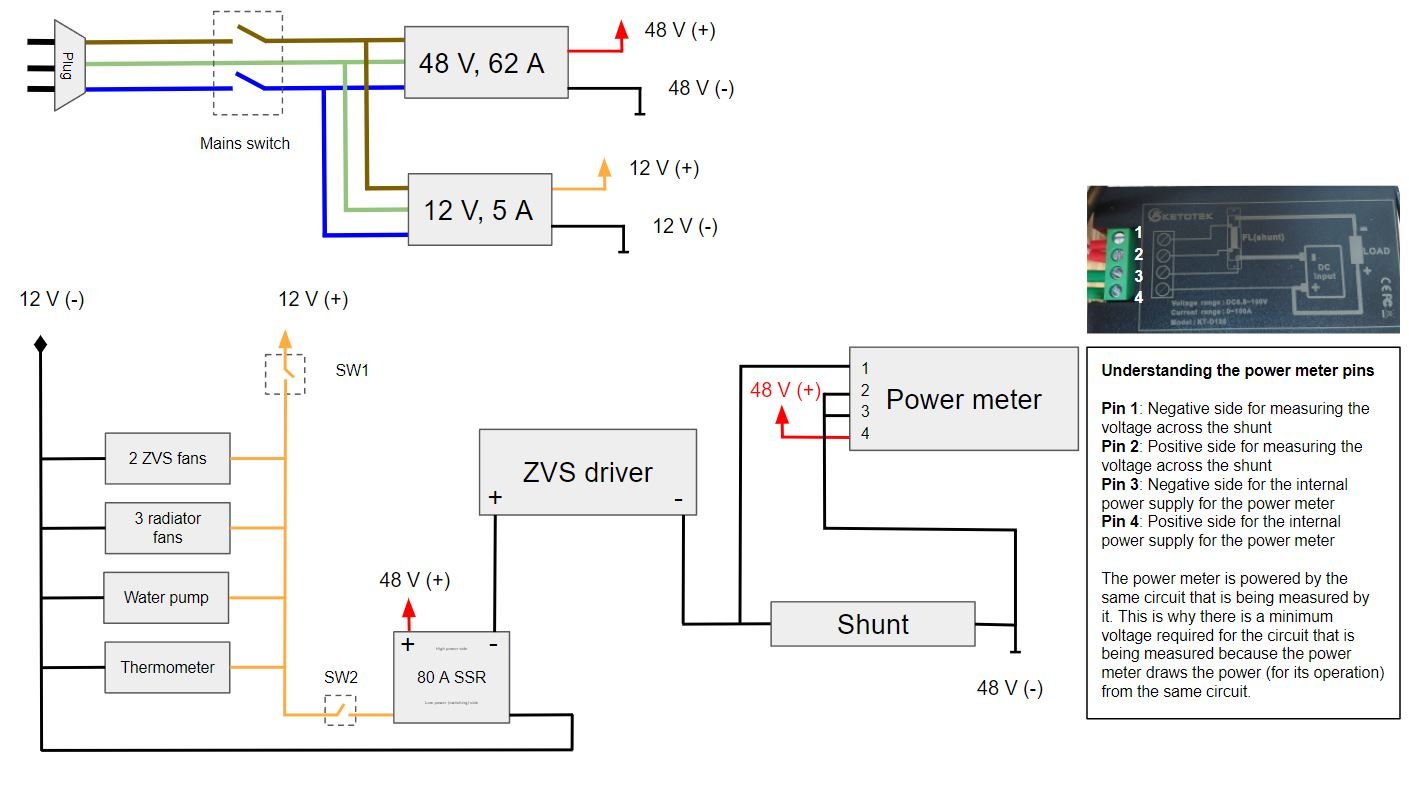

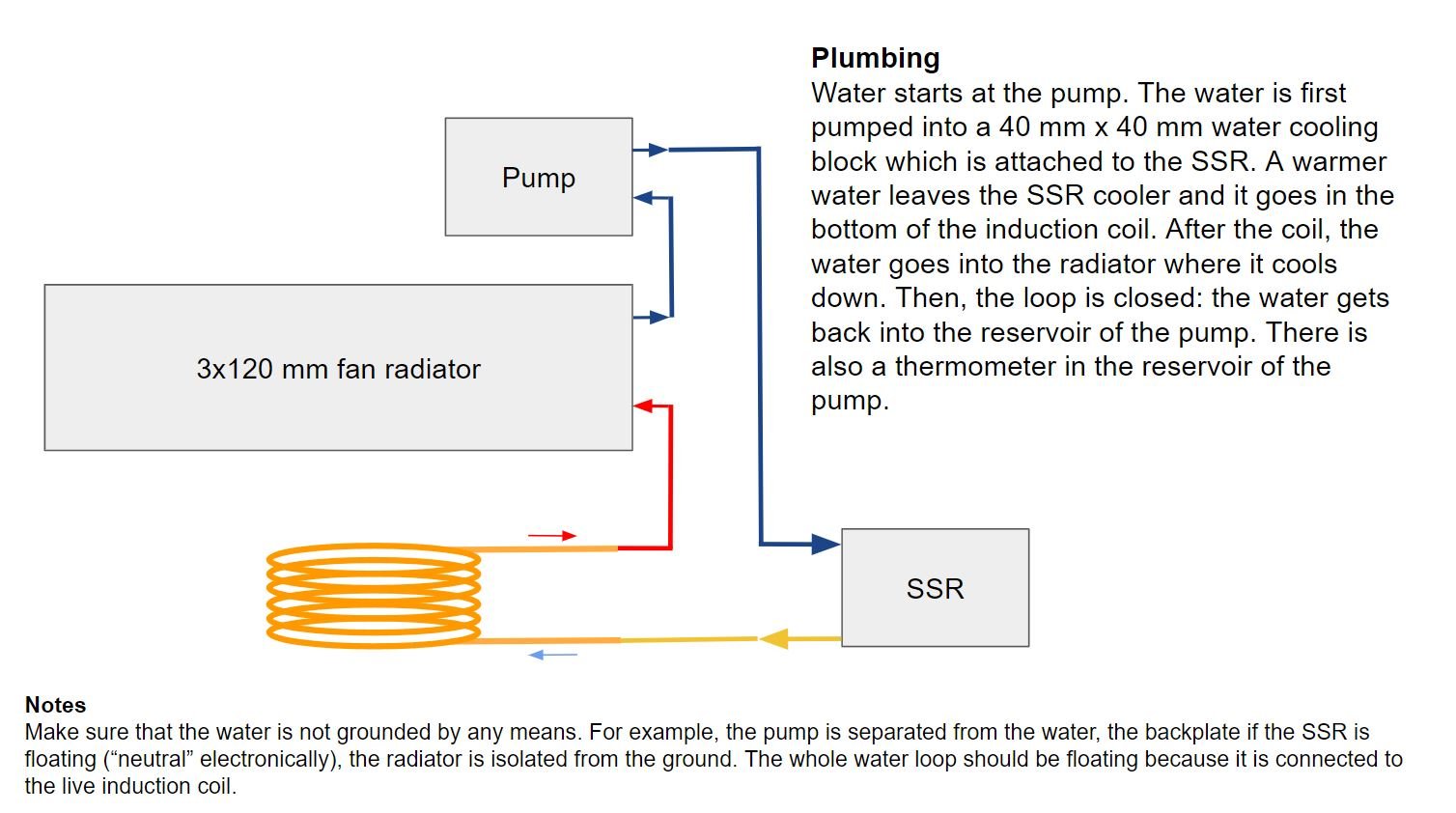

This system is based on a 2500 W ZVS driver. The ZVS driver is powered by a 3000 W telecommunication DC power supply which is capable of supplying 62 A at 48 V; it is perfect for the driver. This enormous power is switched by a 80 A, water-cooled solid state relay (SSR), and the momentary power consumption and related values are measured and displayed by a power meter that utilizes a “100 A, 75 mV” shunt resistor. The SSR and the induction coil needs cooling, therefore I decided to assemble a water cooling system to serve the demands. The cooling system consists of a 12 V water pump and a radiator that can accommodate three 120 mm fans. The SSR is fixed to a 40 mm X 40 mm water cooling block and I added some thermal paste to increase the thermal conductivity across the contact area. The water cooling system is floating (in terms of electrical connections), since the water is in direct contact with the live induction coil. The power meter is powered by the 48 V power supply, and for the rest of the components (fans, pump, thermometer), I added a 12 V 5 A power supply. As you will see in the schematics, we first need to switch on the cooling in order to be able to switch the SSR and power up the ZVS driver. It works the other way too: if you switch the cooling off while the ZVS is still running, the ZVS is also shut down.

Schematics and additional photos

I used the following parts for this device. If you use these affiliate links, you are supporting my work:

Join my YouTube membership

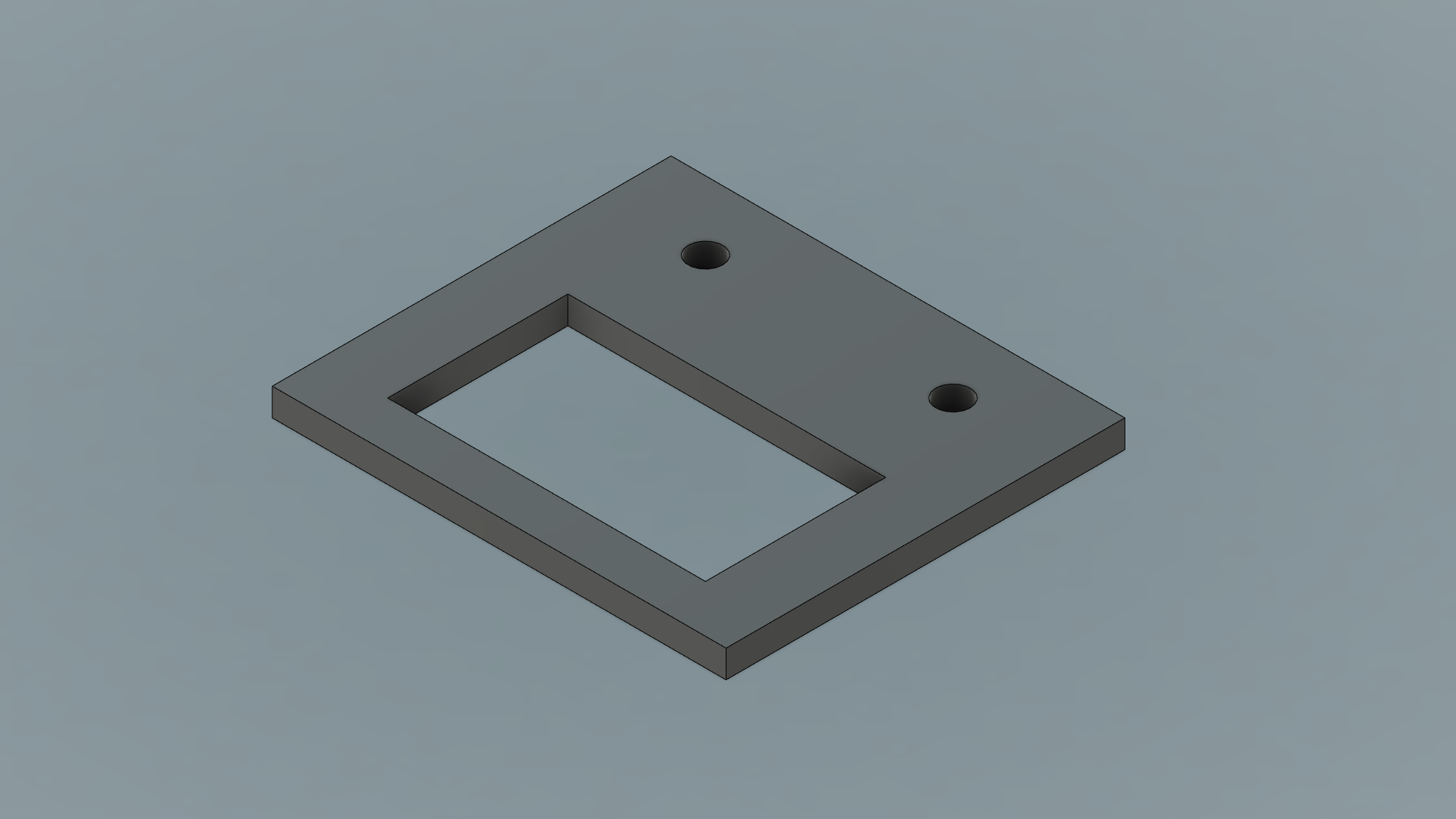

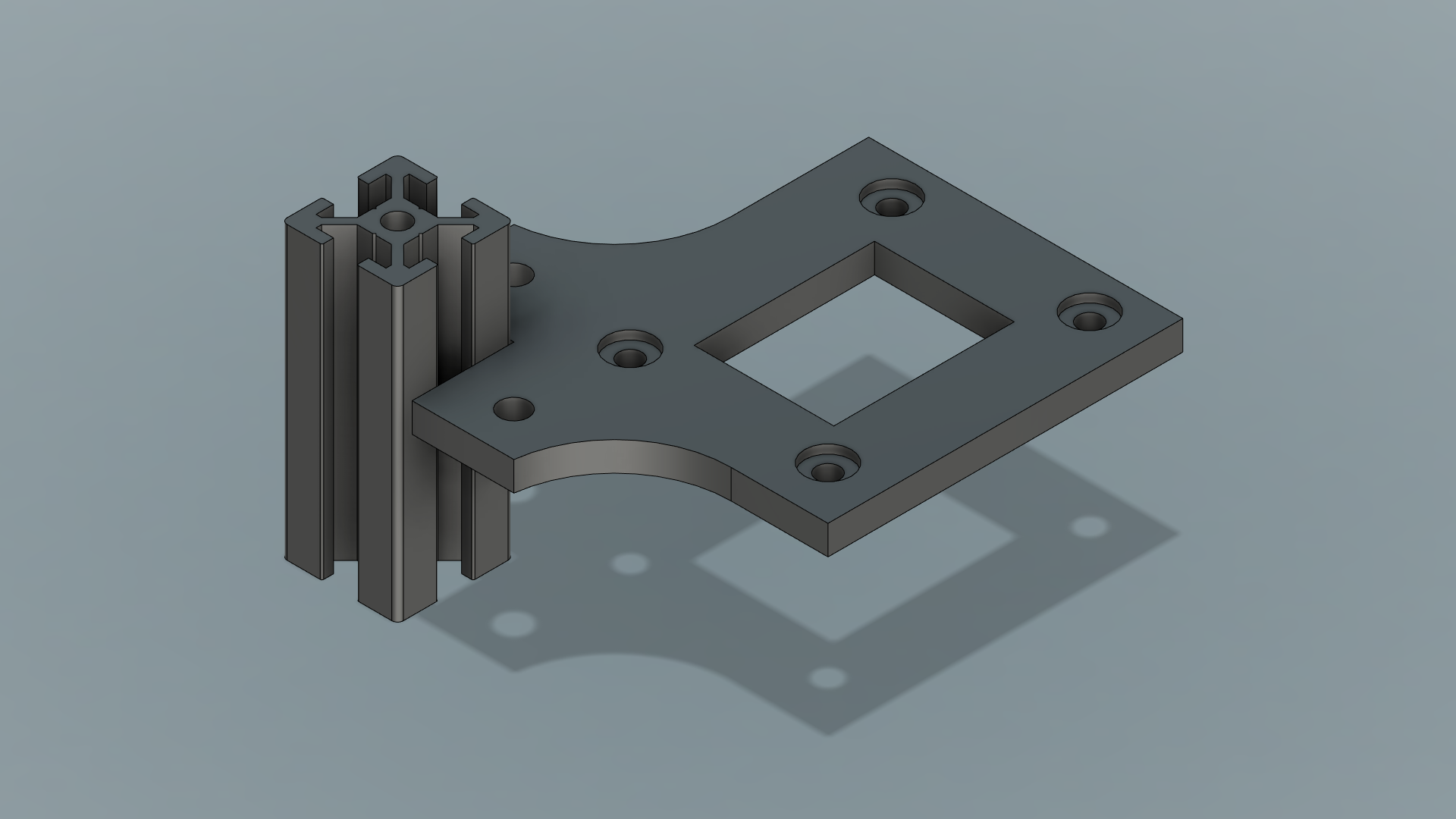

3d-printable parts

Disclaimer: Dimensional discrepancies can occur, I don’t take the responsibility if the parts do not fit.

If you don’t have a 3d printer, I strongly recommend PCBWay’s 3d printing services. Visit pcbway.com and upload these files.