Stepper motor control with buttons and rotary encoder

In this video I show you how to control your stepper motor using 2 buttons (direction control) and a rotary encoder (speed control). The code is relatively short and simple. I used the AccelStepper library as usual.

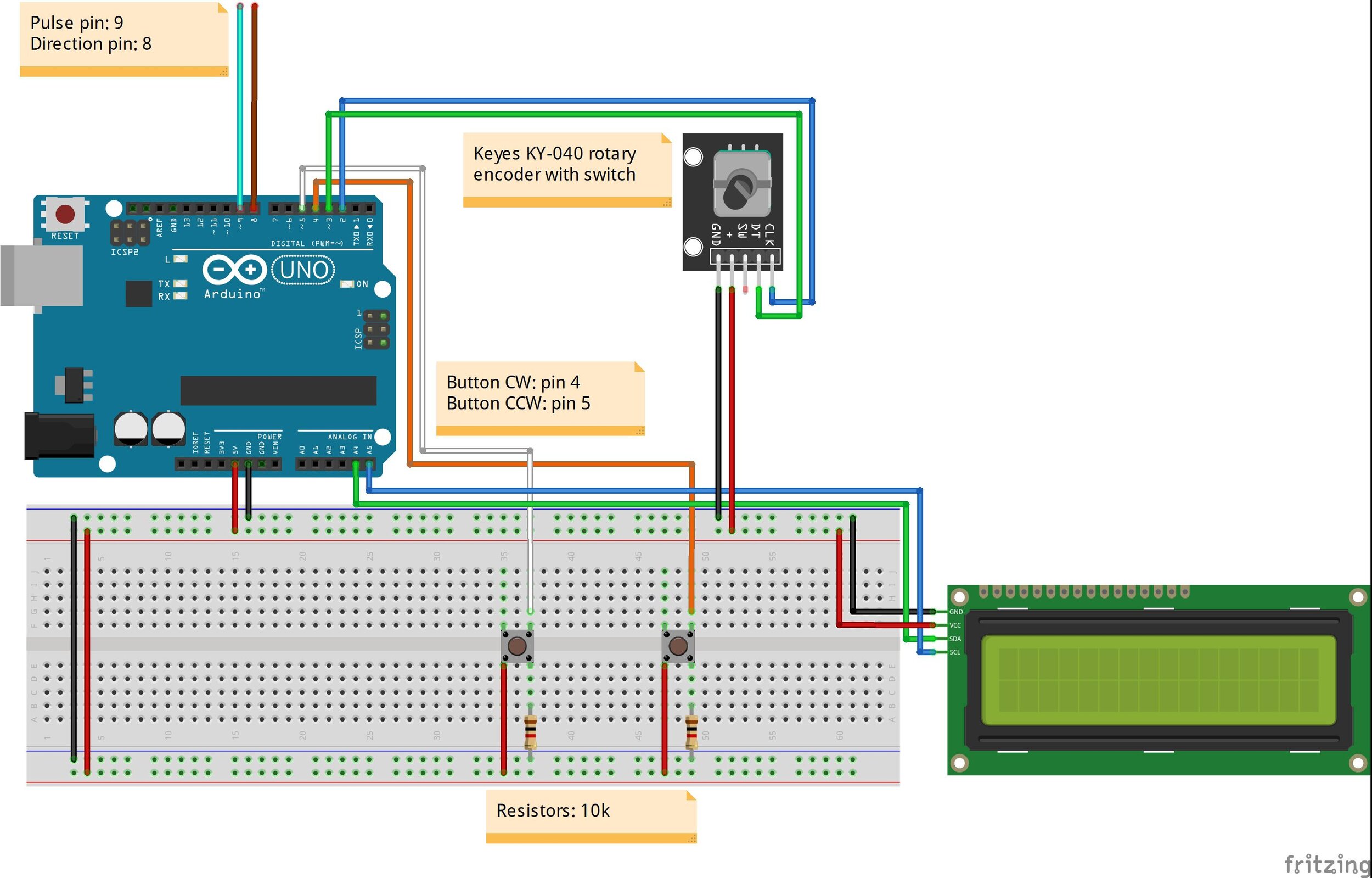

The schematics of the circuit used in the demonstration. The TB6600 stepper motor driver was not added to the drawing but only the step and direction wires coming from the Arduino. The TB6600 can be exchanged with an Easy Driver or a DRV8825 or an A4988 stepper motor driver. All four drivers work with the same principle, therefore they just need the step and direction signals from the microcontroller and that’s all.

Arduino source code

#include <AccelStepper.h> //AccelStepper library AccelStepper stepper(1, 9, 8);// pulses Digital 9 (CLK); Direction Digital 8 (CCW) //16x2 LCD #include <LiquidCrystal_I2C.h> //SDA = A4, SCL = A5 LiquidCrystal_I2C lcd(0x27, 16, 2); //Defining pins const int RotaryCLK = 2; //CLK pin on the rotary encoder const int RotaryDT = 3; //DT pin on the rotary encoder const int ButtonCW = 4; //Button for clockwise rotation const int ButtonCCW = 5; //Button for counterclockwise rotation //Defining variables int RotateCounter = 0; //initial position int MotorSpeed = 50; //some default value for steps/s //Statuses int CLKNow; int CLKPrevious; int DTNow; int DTPrevious; // Time float TimeNow1; float TimeNow2; void setup() { Serial.begin(9600); //------------------------------------------------------ lcd.init(); // initialize the lcd lcd.init(); lcd.backlight(); //------------------------------------------------------ lcd.setCursor(0,0); //Defining positon to write from first row,first column . lcd.print("Button stepping with"); lcd.setCursor(0,1); lcd.print("AccelStepper()"); //You can write 16 Characters per line . delay(1000); //wait 1 sec //------------------------------------------------------ pinMode(2, INPUT_PULLUP); //we use the internal pullup resistor pinMode(3, INPUT_PULLUP); pinMode(4, INPUT); //CW button pinMode(5, INPUT); //CCW button //Store states CLKPrevious = digitalRead(RotaryCLK); DTPrevious = digitalRead(RotaryDT); attachInterrupt(digitalPinToInterrupt(RotaryCLK), rotate, CHANGE); stepper.setMaxSpeed(1000); //SPEED = Steps / second stepper.setAcceleration(5000); //ACCELERATION = Steps /(second)^2 printLCD(); //Print the things on the LCD TimeNow1 = millis(); //Start time } void loop() { //The motor only runs when one of the buttons are kept pressed CheckButtons(); //Checking the status of the buttons RunTheMotor(); //Running the motor TimeNow2 = millis(); if(TimeNow2 - TimeNow1 > 200) //if the time difference is more than 200 ms (increase the number to print to the LCD less often) { updateLCD(); //Printing LCD (This slows down the stepping significantly, so use it less frequently) TimeNow1 = millis(); } } void updateLCD() { //this function only updates the necessary parts lcd.setCursor(7,0); lcd.print(" "); //first we clear the area with spaces (it is important when you show a 3-digit number after a 4-digit number) lcd.setCursor(7,0); lcd.print(MotorSpeed); //Print the speed lcd.setCursor(10,1); lcd.print(" "); lcd.setCursor(10,1); lcd.print(stepper.currentPosition()); //Print the number of steps done from the origin (i.e. the position) } void printLCD() { lcd.setCursor(0,0); // Defining position to write from first row, first column . lcd.print("Speed: "); lcd.setCursor(8,0); lcd.print(" "); lcd.setCursor(8,0); lcd.print(MotorSpeed); //Print the speed lcd.setCursor(0,1); // Defining position to write from second row, first column . lcd.print("Position: "); lcd.setCursor(10,1); lcd.print(" "); lcd.setCursor(10,1); lcd.print(stepper.currentPosition()); //Print the number of pulses } void RunTheMotor() //function for the motor { stepper.enableOutputs(); //enable pins stepper.moveTo(RotateCounter); //tell the stepper to move to the 'RotateCounter'steps (absolute) position while(stepper.distanceToGo() != 0) { stepper.setSpeed(MotorSpeed); stepper.runSpeedToPosition(); //Serial.print("DistanceToGo: "); //for debugging //Serial.println(stepper.distanceToGo()); } //Serial.println(MotorSpeed); //for debugging } void CheckButtons() { //Serial.println(digitalRead(ButtonCW)); //Just for debugging if(digitalRead(ButtonCW) == HIGH) //if the button is pressed { RotateCounter++; //increase the value of the variable, this represents the absolute position of the stepper // Serial.print("ButtonCW: "); //for debugging // Serial.println(stepper.distanceToGo()); //you can add delay here which is also a type of debouncing. It is useful when you want to click the button //once and increase the steps (value of RotateCounter) only by one. //delay(100); //Simplest thing to be able to use this function to add just 1 step at a time to use delay } //Serial.println(digitalRead(ButtonCCW)); //Just for debugging if(digitalRead(ButtonCCW) == HIGH) { RotateCounter--; //decrease the value of the variable, this represents the absolute position of the stepper //Serial.print("ButtonCCW: "); //for debugging // Serial.println(stepper.distanceToGo()); //delay(100); } } void rotate() { CLKNow = digitalRead(RotaryCLK); //Read the state of the CLK pin // If last and current state of CLK are different, then a pulse occurred if (CLKNow != CLKPrevious && CLKNow == 1) { // If the DT state is different than the CLK state then // the encoder is rotating CCW so increase if (digitalRead(RotaryDT) != CLKNow) { MotorSpeed++; } else { // Encoder is rotating CW so decrease MotorSpeed--; } stepper.setSpeed(MotorSpeed); //as this functions is not started from the loop() it is maybe good to update the speed here } CLKPrevious = CLKNow; // Store last CLK state }